11 月. 6, 2025 15:14 Back to list

PVC Privacy Fence

The integrity of concrete footings and ground slabs is paramount to the longevity and stability of the structures they support. A significant, yet often overlooked, threat to this integrity is the development of thermal stresses. As concrete cures and is subjected to daily and seasonal temperature fluctuations, it expands and contracts. When this movement is restricted, immense internal tensile stresses build up, inevitably leading to uncontrolled cracking. These cracks compromise structural strength and can become pathways for moisture and other damaging elements. Hebei Bangjun Metal Products Co., Ltd. provides a robust engineering solution to this universal challenge with our specialized trench mesh. This reinforcing trench mesh is specifically designed to act as a tensile skeleton within the concrete, effectively controlling and distributing these thermal stresses to prevent the formation of cracks.

-

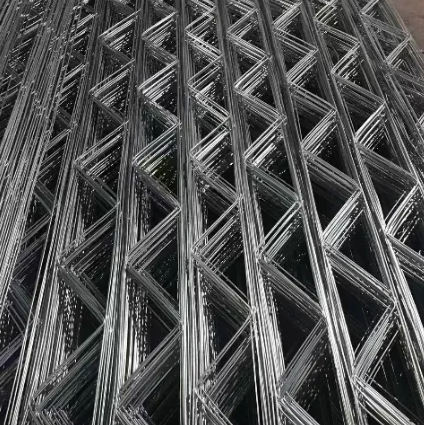

Reinforcing trench mesh

operates on a fundamental principle of composite material behavior. Concrete is exceptionally strong in compression but notoriously weak in tension. Trench mesh, typically a welded grid of steel wires, is embedded in the concrete’s tensile zone to counteract this weakness. When thermal contraction induces tensile forces, the concrete attempts to crack.

- However, the reinforcing trench mesh bridges these potential cracks, absorbing the tensile stress itself. The bond between the steel and the concrete ensures they act as a unified unit, with the mesh holding the concrete together and forcing any micro-cracks to distribute as many fine, harmless hairlines instead of a few large, structurally damaging fissures. This systematic control is why trench mesh is a non-negotiable component in modern concrete foundation work.

- A successful outcome depends on selecting the correct trench mesh supplies for the specific application. Not all projects are identical; the required specification of trench mesh varies based on the load-bearing requirements, the depth and width of the trench, and the soil conditions.

- Key variables include the wire diameter, the grid spacing, and the overall sheet size. Hebei Bangjun Metal Products Co., Ltd. offers a comprehensive range of trench mesh supplies to meet these diverse needs.

- Our technical team can assist in specifying the optimal product, ensuring the reinforcing trench mesh has the correct cross-sectional area and is positioned at the right depth within the concrete to perform its crack-control function most effectively, thereby guaranteeing the long-term performance of the footing.

- Beyond managing thermal movement, trench mesh plays a vital role in distributing both live and dead loads evenly across the concrete foundation. Without reinforcement, point loads or uneven settlement of the subsoil can cause concentrated stress points, leading to localized cracking and failure.

- The integrated grid of the trench mesh helps to spread these loads over a wider area, reducing the stress on any single point of the concrete. This is particularly crucial for trenches that will support load-bearing walls or columns.

- By integrating our reinforcing trench mesh, the foundation becomes a more cohesive and resilient structural element, capable of handling the dynamic and static forces it will encounter throughout its service life.

The primary function of trench mesh in concrete footings is to resist tensile stresses and control cracking. Concrete is weak in tension, and forces from drying shrinkage, thermal contraction, and ground movement can cause it to crack. The trench mesh, positioned within the concrete, acts as a reinforcement that absorbs these tensile forces. It holds the concrete together, preventing the cracks from widening and ensuring they remain as tight, controlled hairlines that do not compromise the structural integrity or durability of the footing.

Reinforcing trench mesh combats thermal cracking by providing tensile strength where the concrete has none. As concrete cools and contracts, it generates internal tensile stress. The reinforcing trench mesh, through the strong bond between steel and concrete, resists this contraction. It forces the concrete to stretch slightly, thereby reducing the tensile stress to a level below its cracking threshold.

When ordering trench mesh supplies, the key specifications to consider are the sheet dimensions, the wire diameter, and the grid spacing. The sheet must be sized to fit the trench correctly. The wire diameter and grid spacing together determine the cross-sectional area of steel per meter, which dictates the tensile strength of the mesh. This is often denoted by a standard product code. The choice depends on the structural engineering requirements for the specific project, including the expected loads and the depth of the concrete pour.

While highly recommended for most applications, trench mesh is not always a strict necessity for every single concrete trench. Its use is critical for load-bearing footings, foundations for walls, and slabs on ground that will be subjected to significant thermal variation or potential ground movement. For very small, non-structural concrete pours, such as a narrow garden path, it may be omitted.

The quality of trench mesh has a direct and profound impact on the longevity of a structure. High-quality trench mesh with strong, consistent welds and the correct wire specification will perform its crack-control function reliably for decades. Poor quality mesh with weak welds can fail under stress, allowing cracks to develop and widen. These cracks allow water and air to reach the steel, leading to corrosion. As the steel rusts, it expands, spalling the concrete and further accelerating deterioration.

-

Characteristics And Advantages Of Gabion Mesh

News11 月. 6, 2025

-

Characteristics And Advantages Of Stainless Steel Woven Mesh

News11 月. 6, 2025

-

Characteristics and Usage Precautions of Barbed Wire

News11 月. 6, 2025

-

Enhance Your Projects with Quality Materials

News11 月. 6, 2025

-

Affordable and Elegant Fencing Solutions for Your Horses

News11 月. 6, 2025

-

The Ultimate Fencing Solutions for Your Horses

News11 月. 6, 2025

-

The Main Application Areas and Usage Precautions of Razor Wire

News11 月. 6, 2025

-

The Main Application Areas of Gabion Mesh

News11 月. 6, 2025

-

Your Go-To Solutions for Welded Wire Mesh

News11 月. 6, 2025

-

Durable Solutions with Galvanized Wire Mesh

News11 月. 6, 2025

-

Build Stronger with Quality Mesh Solutions

News11 月. 6, 2025

-

Find the Best Concrete Wire Mesh for Your Project

News11 月. 6, 2025