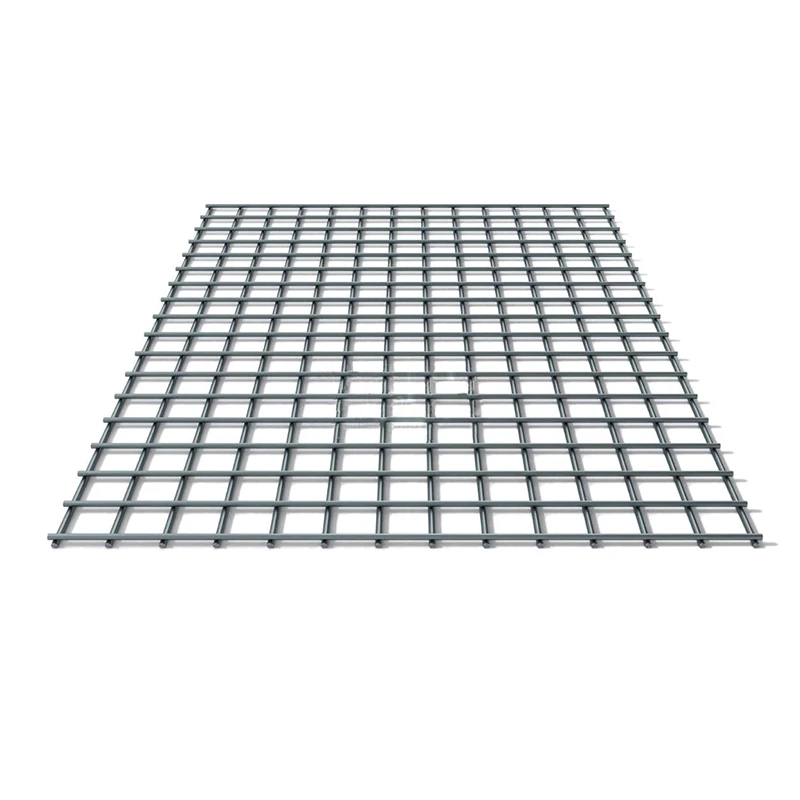

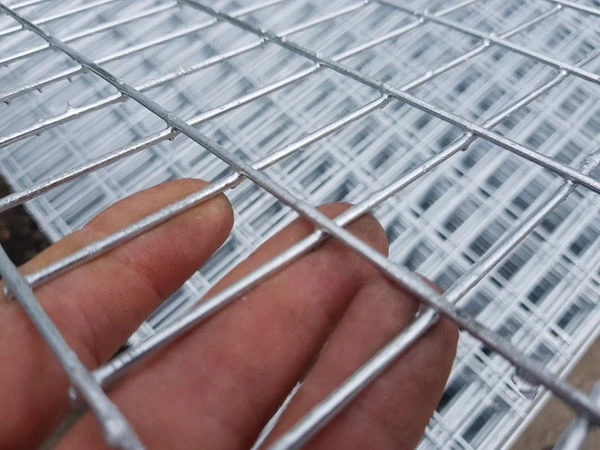

High-Strength Concrete Reinforcement Mesh (AS/NZS 4671:2001)

Hard drawn mesh provides

High yield strength (≥ 485 MPa) for crack-resistant concrete structures

High tensile strength (775–855 MPa) for both short-term impact and long-term load stability

Lightweight design to facilitate transportation and installation

Strong weld points (shear strength ≥ 250 N/mm²) to maintain mesh integrity during handling and concrete pouring

With these features, Hard Drawn Mesh not only shortens construction cycles and reduces labor costs but also enhances the durability and safety of concrete structures.

Technical Specifications

|

Parameter |

Specification |

Description |

|

Wire Diameter |

4.0–12 mm |

Customizable according to project requirements |

|

Mesh Size |

150 × 150 mm / 300 × 300 mm |

Suitable for different load-bearing needs |

|

Sheet Size |

Standard: 4.65 × 1.97 m, Large: 6.15 × 2.42 m |

Single sheet coverage: 9.16–14.87 m² |

|

Yield Strength |

≥ 485 MPa |

Ensures long-term load-bearing capacity |

|

Tensile Strength |

775–855 MPa |

Maintains structure under stress |

|

Elongation |

≥ 10% |

Provides ductility to prevent brittle failure |

|

Weld Shear Strength |

≥ 250 N/mm² |

Maintains mesh stability |

|

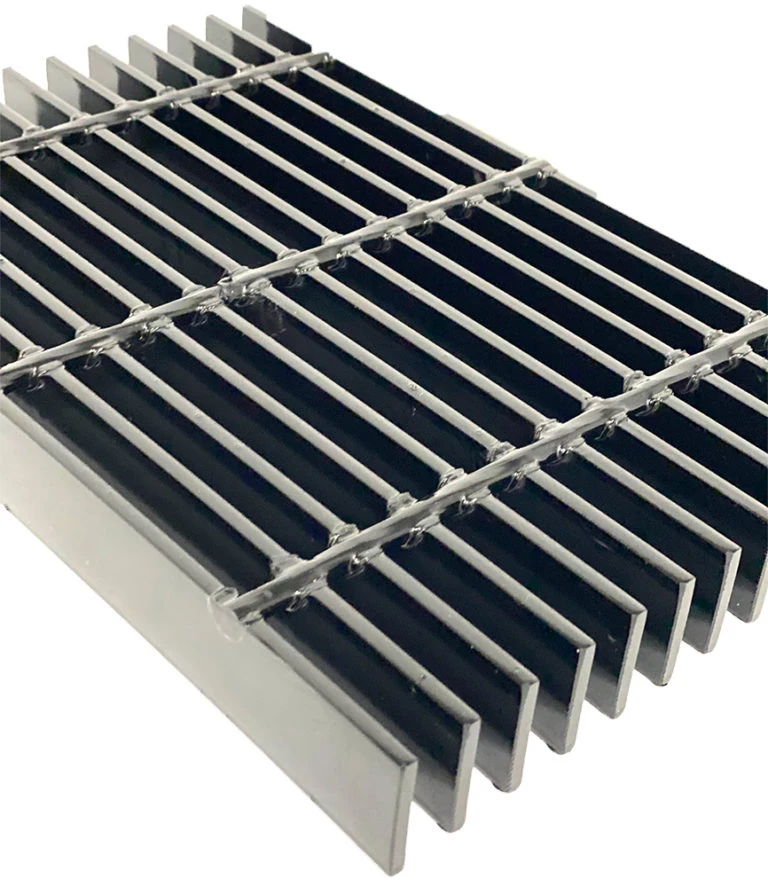

Surface Treatment |

Black, Hot-Dip Galvanized (HDG), Epoxy Coated |

Enhances corrosion resistance and service life |

All values are based on AS/NZS 4671:2001 testing standards with ±5% tolerance.

Standard Models

|

Model |

Pitch / certres |

Wire dia.(mm) |

Length (mm) |

Width (mm) |

Newt cover (sqm) |

bangjun reinforcing item |

Cross section sqmm / m |

Mass per sqm kg / sqm |

No. of Longitudinal wire |

No. of Cross Wire |

Overhangs of Longitudianal wire |

Overhangs of Cross wire |

Weight (kg) |

|

668 |

150 |

4 |

4650 |

1970 |

7.525 |

668L |

83.8 |

1.315 |

14 |

31 |

75/75 |

10/10 |

12.44 |

|

665 |

150 |

5.3 |

4650 |

1970 |

7.525 |

665L |

147.1 |

2.309 |

14 |

31 |

75/75 |

10/10 |

21.85 |

|

663 |

150 |

6.3 |

4650 |

1970 |

7.525 |

663L |

207.8 |

3.263 |

14 |

31 |

75/75 |

10/10 |

30.87 |

|

665 |

150 |

5.3 |

6150 |

2420 |

12.76 |

665E |

147.1 |

2.309 |

17 |

41 |

75/75 |

10/10 |

35.29 |

|

663 |

150 |

6.3 |

6150 |

2420 |

12.76 |

663E |

207.8 |

3.263 |

17 |

41 |

75/75 |

10/10 |

49.86 |

|

662 |

150 |

7.1 |

6150 |

2420 |

12.76 |

662E |

263.9 |

4.144 |

17 |

41 |

75/75 |

10/10 |

63.33 |

|

661 |

150 |

7.5 |

6150 |

2420 |

12.76 |

661E |

294.5 |

4.624 |

17 |

41 |

75/75 |

10/10 |

70.67 |

|

300 Centres of hard drawn steel wire fabric |

|||||||||||||

|

668 |

300 |

5.6 |

4950 |

2220 |

10.08 |

84/10 |

82.1 |

1.289 |

4*5.6mm+4*4.0mm |

19 |

25/25 |

10/10 |

15.85 |

|

665 |

300 |

7.5 |

4950 |

2220 |

10.08 |

147/10 |

147.3 |

2.312 |

6*7.5mm+4*5.3mm |

19 |

25/25 |

10/10 |

28.36 |

|

665 |

200 |

6.1 |

5050 |

2020 |

8.312 |

SE62 RES |

146.1 |

2.294 |

11 |

26 |

25/25 |

10/10 |

24.79 |

|

665 |

200 |

6.1 |

5850 |

2420 |

11.93 |

SE62 |

146.1 |

2.294 |

13 |

30 |

25/25 |

10/10 |

34.1 |

|

665 |

300 |

7.5 |

6050 |

2420 |

11.58 |

SE73 |

147.3 |

2.312 |

9 |

21 |

25/25 |

10/10 |

36.51 |

|

665 |

300 |

7.5 |

5000 |

2270 |

10.08 |

SE73DE |

147.3 |

2.312 |

8*7.5mm+2*5.5mm |

19 |

7.5mm:25/255.5mm:25/25 |

10/10 |

30.69 |

|

664 |

200 |

7 |

5650 |

2220 |

10.432 |

SE72 |

192.4 |

3.02 |

12 |

29 |

25/25 |

10/10 |

39.93 |

|

662 |

200 |

8 |

5650 |

2220 |

10.432 |

SE82 |

251.3 |

3.946 |

12 |

29 |

25/25 |

10/10 |

52.16 |

|

661 |

200 |

9 |

6100 |

2420 |

12.76 |

SE92 |

318 |

4.99 |

12 |

29 |

25/25 |

10/10 |

71.65 |

More details of hard drawn mesh and seismic grade reinforcing mesh

|

Model |

BJ reinforcing item |

Uniform Elongation % |

0.2% proof stress |

Ratio Rm/Re |

Wire diameter |

||

|

Min(Mpa) |

Max(Mpa) |

||||||

|

668 |

668L |

≥1.5% |

485 |

|

≥1.03% |

>5.0mm |

|

|

665 |

665L |

||||||

|

663 |

663L |

||||||

|

665 |

665E |

||||||

|

663 |

663E |

||||||

|

662 |

662E |

||||||

|

661 |

661E |

||||||

|

668 |

84/10 |

||||||

|

665 |

147/10 |

||||||

|

668 |

668L |

≥1.5% |

485 |

750 |

≥1.03% |

≥5.0mm |

|

|

665 |

665L |

||||||

|

663 |

663L |

||||||

|

665 |

665E |

||||||

|

663 |

663E |

||||||

|

662 |

662E |

||||||

|

661 |

661E |

||||||

|

668 |

84/10 |

||||||

|

665 |

147/10 |

||||||

|

Model |

BJ reinforcing item |

Uniform Elongation % |

Yield Strength |

Tensile Ratio |

Weld Shear Strength |

||

|

Min(Mpa) |

Max(Mpa) |

Min |

Max |

||||

|

665 |

SE62 RES |

≥10% |

500 |

600 |

1.15 |

1.4 |

>5.9 |

|

665 |

SE62 |

>7.3 |

|||||

|

665 |

SE73 |

>11.0 |

|||||

|

665 |

SE73DE |

>5.9 |

|||||

|

664 |

SE72 |

>5.9 |

|||||

|

662 |

SE82 |

>5.9 |

|||||

|

661 |

SE92 |

>5.9 |

|||||

Custom wire diameters, mesh sizes, and sheet dimensions are available to meet special structural or seismic design requirements.

Key Advantages

High-Strength Performance

Cold-drawn steel increases yield strength by 25–30%, providing excellent crack resistance

Strong weld points maintain mesh integrity during handling and concrete pouring

Construction Efficiency

Large sheet coverage reduces installation time by 10–15%

Lightweight and easy to handle, minimizing labor and equipment costs

Durability & Sustainability

Optional hot-dip galvanization or epoxy coating improves corrosion resistance

Optimized material usage reduces steel waste and overall project carbon footprint

Customizable Design

Wire diameter, mesh spacing, and sheet size can be tailored to project specifications

Seismic-grade mesh options available for high-strength or anti-seismic structures

Cost-Effective & Reliable

Lighter mesh reduces transportation and installation costs

Stable production ensures consistent quality and lowers project risk

Typical Applications

Residential & Commercial Construction: floor slabs, walls, foundations

Industrial Facilities: factory floors, warehouses, logistics centers

Roads & Infrastructure: sidewalks, driveways, parking lots

Precast Concrete Elements: panels, culverts, bridge decks

High-Strength & Seismic Projects: airport runways, high-rise buildings, earthquake-resistant structures

Suitable for light to heavy loads, general to seismic-grade reinforcement, providing a one-stop solution for concrete reinforcement.

Why Choose Hard Drawn Steel Wire Fabric

International Standard Compliance: fully certified AS/NZS 4671:2001, ensuring smooth project approvals

High Cost Efficiency: reduced material weight and installation labor

Enhanced Construction Efficiency: large sheet coverage and strong weld points

Customizable Solutions: wire diameter, mesh size, sheet dimensions, and coatings tailored to project needs

Technical & After-Sales Support: sample provision, specification documents, and construction guidance available

Contact Us

For quotes, technical specifications, or sample requests, contact Bangjun Metal:

Email: sai@bangjunmetal.com

Submit your project requirements today to receive a tailored solution with fast delivery and professional support!

Related Product

News